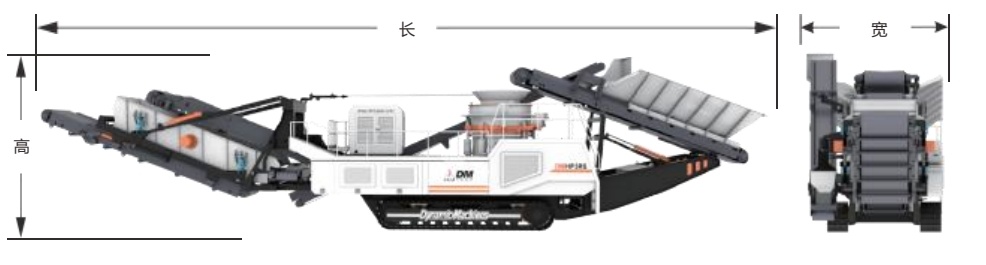

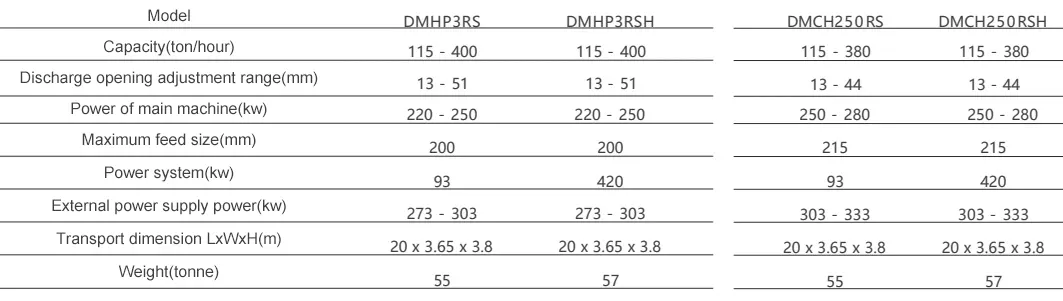

Paraguay DMHP3RS/CH250RS crawler mobile cone crushing plant

Category:

ParaguayMobile Crushing Stations

Product Description

DMHP3RS/CH250RS Crawler Mobile Cone Crushing Plant

Shipping dimensions schematic

Standard: external power supply mode

Simple and efficient, equipment maintenance and operating costs are greatly reduced, diesel engine-driven crawler travel and equipment extension and folding, equipment site in place after the external 380V (50HZ) three-phase power supply for the host operation and other operations to provide power.

Option: oil-electricity dual power mode

Product Introduction:

The Mobile Cone Crushing Plant is the ideal choice for many stand-alone secondary crushing processes due to its unique optimised dynamic design and intelligent process control system, which makes it robust, stable and reliable with high crushing efficiency.

Product Advantages

Heavy plate hammer design, larger feed size, larger crushing ratio, higher production capacity, more excellent finished material grain shape.

Hydraulic opening crusher frame, maintenance is easy and safe, convenient for later equipment maintenance.

Foldable side discharge belt conveyor, no need to dismantle for transport.

Iron remover/return system/feeding system, flexible options to adapt to customer needs.

Adopting intelligent wireless remote control device to control the crawler travelling, a single person can remotely operate up and down the special flatbed trailer, to achieve rapid transfer operations.

Feeding device

Large size standard hopper for quick and easy feeding.

Grate vibrating feeder ensures stable and even feeding to the crushing machine.

Grate bars can pre-screen the material to improve the purity of the finished product.

Crushing Mainframe

Adjust the discharge opening with double wedges, convenient and quick

Optimised cavity design for high output and high crushing ratio.

Powerful crusher drive ensures high crushing capacity and stable reliability.

Drive system

Efficient and powerful engine - electric drive

Energy-saving effect is obvious (crushing mainframe and all conveyor belts are electric drive), external power electricity makes crushing more economical.

Electricity connection is used to supply power to downstream equipments such as screening equipments, stacking belts, etc.

Intelligent wireless remote control, convenient for operation and mobile transfer

Main belt conveyor & iron remover

Wide, strong main belt, discharge height up to 4 metres

Adoption of high strength conveyor belt, service life increased by more than 1.5 times

Permanent magnetic separator, stable, long service life

Feedback system

Increased crusher utilisation through innovative continuous feeding system

Vibratory feeder and pre-screener conveyor speeds can be automatically adjusted according to the crusher level for optimum utilisation of the crusher.

Return belt can be rotated 90° for direct discharge

Tail sieve combinations

Can be used to produce aggregate or for inspection screening.

Wider screen surface, greatly increasing the screening capacity.