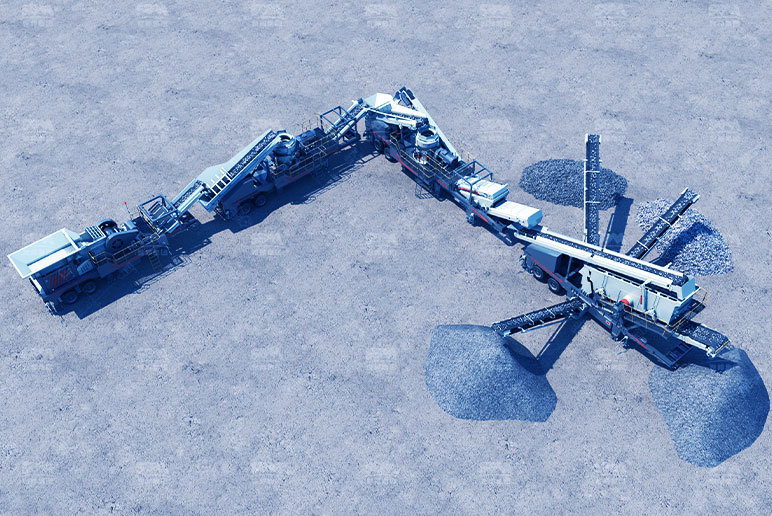

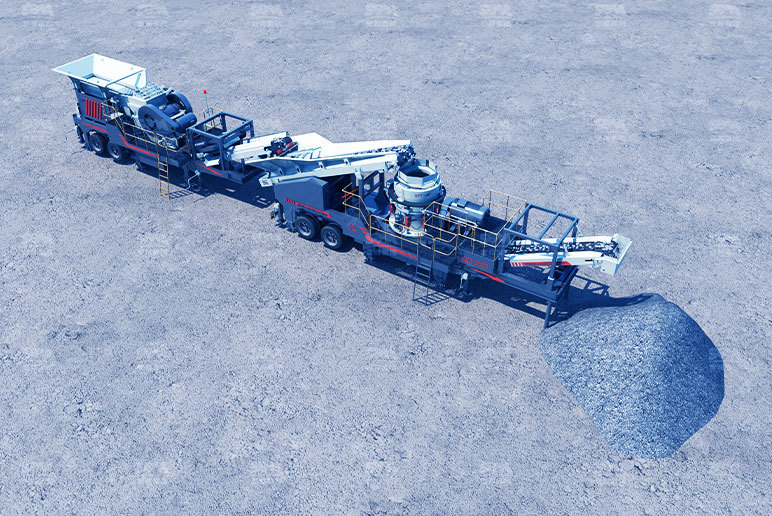

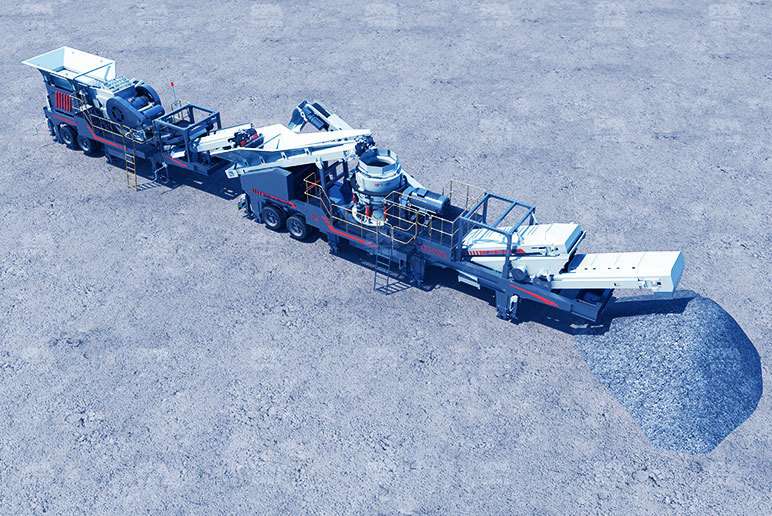

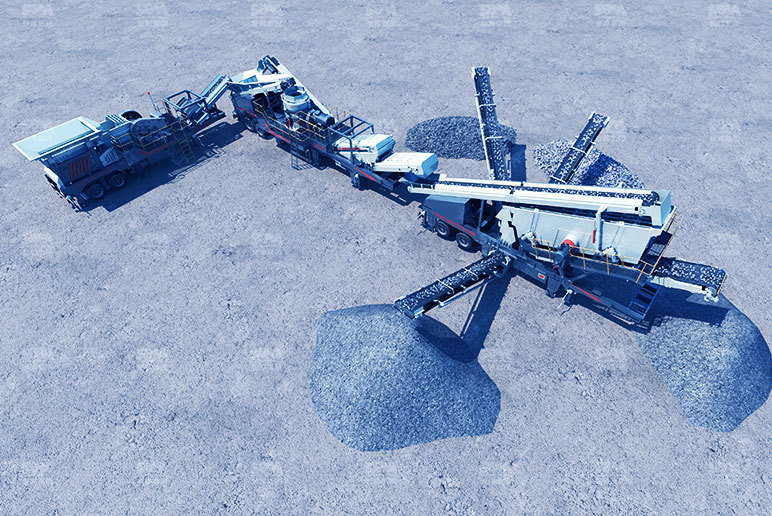

NK Series medium and fine crushing and screening mobile station

The medium and fine crushing and screening mobile plant is equipped with high performance and high production capacity CS, HST or HPT series cone crusher, which is suitable for two-stage and three-stage crushing, and it is better than the old cone crushing in terms of performance, efficiency, production capacity and finished product quality.

Graphic Details

The medium and fine crushing and screening mobile plant is equipped with high-performance and high-capacity CS, HST or HPT series cone crusher, which is suitable for two-stage and three-stage crushing, and it is better than the old cone crushing in terms of performance, efficiency, production capacity, and quality of finished products. Nine cone crusher models and six impact crusher models with fairly good finished product shapes are available, and are equipped with screens to classify the materials or move them to the next crushing section.

Applications: concrete and waste recycling, construction waste processing, quarries, coal mining industry

Materials: construction waste, iron ore, manganese ore, river pebbles, granite, limestone, river stone, aluminium ore, etc.

Product Advantages

■ Customised mainframe

The mainframe is specially developed and customised for the mobile station, with reliable performance, high output, high energy utilisation and easy maintenance and adjustment. Simple operation and easy maintenance.

■ Modular design

Overall modular design, universal interchangeability. When there is an order, it can be quickly assembled into the required mobile station model, reducing the production cycle and meeting the customer's demand for fast delivery.

■ Thin oil self-lubrication

Vibrating screen adopts thin oil self-lubrication, good lubrication effect, long maintenance cycle, 8 months to replace the lubricant can be, saving lubricant and labour costs.

■ New style jawbreaker

PE3040 jawbreaker adopts new technology design, long service life, high crushing ratio, and can quickly adjust the discharge opening to meet the product requirements of different crushing applications.

■ Foundationless installation

All parts are completely on-board, no dismantling parts for transport, eliminating the need for on-site installation; the reasonable adjustable fixed leg design effectively realises foundationless installation.

■ Convenient and flexible

No external belt conveyor, no need for cranes and erection of belt conveyors on site, quick installation and commissioning, and 24-hour production when transferring to other sites, realising the superiority of convenient and flexible mobile station.

■ Intelligent control

The new vehicle-mounted integrated intelligent automatic control system is adopted, which makes the operation, maintenance and adjustment of the crushing process more convenient and accurate.

Typical process

Two-stage crushing mix without screening

Two-stage crushing mix with product control screening

Two stage one closed circuit crushing + screening (hard rock/soft rock )

Three stages of one closed-circuit crushing + screening